- yuanchenwujin@hotmail.com

- +86 335 3899 615

- 中文站

Product Details

Ball Tests Equipment

227 g 2260 g Ball Test Machine ISO 3537

Mechanical Test Equipment for 227 g and 2260 g according to ISO 3537. Drop height form 1 m to 12 m. Samples 300mm

Purpose of test:

The purpose of this test is to determine whether the safety glazing material has a certain minimum strength and cohesion under impact from a small hard object.

Hardened steel ball

227 g, 38 mm

2260 g, 82 mm

Hardened steel ball, with a mass of (227 ± 2) g and a diameter of approximately 38 mm. Means for dropping the ball freely from a height to be specified, or means for giving the ball a velocity equivalent to that obtained by the free fall.

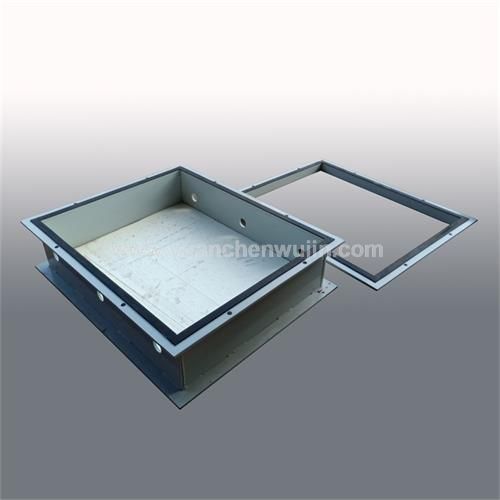

Supporting fixture:

composed of two steel frames, with machined borders, 15 mm wide, fitting one over the other and faced with rubber gaskets about 3 mm thick and 15 mm wide, of hardness 50 IRHD, determined in accordance with ISO 48. The lower frame rests on a steel box, about 150 mm high. The test piece is held in place by the upper frame, the mass of which is about 3 kg. The supporting frame is welded on a sheet of steel 12 mm thick, resting on the floor, with an interposed sheet of rubber, about 3 mm thick, of hardness 50 IRHD

Test piece: The test piece shall be a flat square with 300 mm

Procedure

Condition the test piece at the specified temperature for at least 4 h immediately preceding the test. Place the test piece in the fixture. The plane of the test piece shall be perpendicular, with 3°, to the incident direction of the ball. When necessary to retain the test piece in the fixture, it shall be clamped to ensure that the movement of the test piece during test will not exceed 2 mm at any point along the inside perhipery of the fixture.

The point of impact shall be within 25 mm of the geometric centre of the test piece for a drop height less than or equal to 6 m, and within 50 mm of the centre of the test piece for a drop height greater than 6 m. The ball shall strike the face of the test piece which represents the outside face of the safety glass when mounted on the vehicle. The ball shall be allowed to make only one impact.

Steel ball lifting device

Impact Height: 1m, 3m, 5m, 12m customizable

Steel ball releasing device

Electromagnet

Various of testing equipment

No. | Name | ID | Description |

Impact Resistance | |||

1 | Shot Bag Impact Frame | YC-PS-02 | Automatic Release/Electric Lifting/Pneumatic Clamping |

2 | YC-Z-1954 | Manual Release/Manual Lifting/Mechanical Clamping | |

3 | Shot Bag | YC-S01-11 | 25 lbs |

4 | YC-S01-25 | 25kg | |

5 | YC-S01-45 | 45Kg | |

6 | YC-S01-46 | 46Kg | |

7 | Pneumatic Tyres Impactor | YC-PT-01 | 50kg/3.50-R8 4PR |

8 | Resistance Measurement Ball | YC-R-76 | Diameter 76mm / Maximum Range 30N / Accuracy: ± 0.5% |

9 | 1 m Ball Impact Tester | YC-C-01 | Manual release/Maximum impact height 1 m/Include 610mm*610mm support |

10 | 2 m Ball Impact Tester | YC-C-02 | Maximum impact height 2 m/Include 610mm*610mm support |

11 | 5 m Ball Impact Tester | YC-C-05 | Auto Lifts and release/Maximum impact height 5 m/Include 300mm*300mm and 610mm*610mm support |

12 | 12 m Ball Impact Tester | YC-C-12 | Auto Lifts and release/Maximum impact height 12 m/Include 300mm*300mm and 610mm*610mm support |

13 | Support for Ball Tests | YC-FB-1000 | 610mm*610mm |

14 | Support for Ball Tests | YC-FB-300 | 300mm*300mm |

15 | Ball Falling Release Device | YC-ARD-01 | Auto Release Device |

16 | Support for Impact Resistance | YC-C-MS | 40mm*40mm/Cover Glass for windows of mobile electronic devices |

17 | Hardened-steel Ball | YC-GQ-227 | 227g/38mm |

18 | YC-GQ-508 | 508g/50mm | |

19 | YC-GQ-1040 | 1040g/63mm | |

20 | YC-GQ-2260 | 2260g/82mm | |

21 | Headform | YC-R01-ZJ10 | 10kg |

22 | Wool Felt for Headform | YC-R01-ZJ89 | Radius 89mm |

23 | Supporting Fixture for Headform | YC-R02-ZJ10 | 1100mm*500mm |

24 | Pummel Machine | YC-Q-02 | Auto Pummel / Automatic Movement / Max Sample 300mm * 300mm / Max Gap 15mm |

Tempered Glass Flatness | |||

25 | Flatness Measure Instrument | YC-C01-300 | Measuring Span 300 mm |

26 | YC-C01-500 | Measuring Span 500 mm | |

Static Load Test | |||

27 | Static Load Tester | YC-PV-2400 | 2400Pa/Sandbag/Samples: 1643mm*991mm~2009mm*1027mm (Customized) |

High Temperature Test | |||

28 | Two-step Method of Boil Test Device | YC-B02-300 | 66°C for 3 min and then 100°C for 2 h / 6 samples with 300mm |

29 | One-step Method of Boil Test Device | YC-B01-300 | Directly 100°C for 2 h / 6 samples with 300mm |

Optical Measure | |||

30 | Optical-distortion Test Instrument | YC-GJ-01 | Include Support Stand |

31 | Secondary-image-separation Test Instrument | YC-BS-01 | Target Test/Include Support Stand |

Appearance Inspection | |||

32 | Hollow Glass Observation Case | YC-OB-01 | |

Radiation Test | |||

33 | Radiation Resistance Testing Machine | YC-NFZ-02 | |

Pendulum Shock Test for Electric Lifts | |||

34 | Soft Pendulum Shock Device | YC-S01-45 | 45Kg |

35 | Hard Pendulum Shock Device | YC-S01-10 | 10Kg |

Impact Test for Doorsets | |||

36 | Soft Heavy Body Impactor | YC-Z01-30 | 30Kg |

Forced Entry Resistant Glass Impact | |||

37 | Forced Entry Resistant Glass Tester | YC-FZ-01 | |

Impact Test of Heavy Objects for Glass and Metal Guardrail for Building | |||

38 | Solid Steel Ball | YC-GQ-E1040 | 1040g/With hook |

39 | Shot Bag Impactor | YC-S01-45 | |

Sound Insulation Test | |||

40 | Sound Insulation Testing Equipment | YC-SI-01 | 300mm×300mm |

Others | |||

41 | Dew Point Meter | YC-L01-80 | Dry Ice -80°C |

42 | Crush Pen | YC-J01 | 75g±0.3g/Radius of Curvature of the Point 0.2mm ± 0.05 mm |

43 | Temperature and Humidity Meter | YC-M-01 | 1°C/2% |

44 | Measure Tape | YC-TC-01 | 1mm |

45 | Calipers | YC-TC-02 | 0.02mm |

46 | Steel Ruler | YC-TC-03 | 1mm |

47 | Electronic Balance | YC-EB-01 | 0.1g |

48 | Feeler Gauge | YC-FG-01 | 0.01mm |

Agency Business | |||

Sales Agency of Beijing Aoptek Science Co.,Ltd. for All testing equipment(ex-factory price) | |||

49 | Measurement Instrument for Energy-saving Glass | GlasSmart 1000 | Various of parameters can be measured and calculated with Non Destructive and on-site |

Complete the measurement and calculation of all parameters of optical and thermal according to relevant standards | |||

T(λ), ρ(λ), Tv, Pv, L* a* b*, Te, Pe, ae, g, gIR, SC, SHGC, LSG, Emissivity, Glass Thickness, Spacer Thickness | |||

Applicable to owners, designers, construction, supervision units and quality inspection agencies | |||

50 | U Value Meter For IG | GlassMeter 800K | IG Thickness、Low-E Position, Emmisivity, U Value |

Notes | Refer to international standards (ISO/EN) and can be processed as required. | ||

All delivery time is subject to contract | |||

Equipment prices may vary due to raw material market reasons, subject to actual contract | |||

All of the above are ex-factory prices and do not include on-site installation and commissioning costs / Negotiated if necessary | |||

Qinhuangdao Yuanchen Technology Equipment Co.,Ltd. Qinhuangdao Yuanchen Hardware Co., Ltd. www.yuanchenwujin.com www.yuanchenkeji.net Email: yuanchenwujin@hotmail.com yuanchenkeji@hotmail.com Tel: 0086-335-7963298 3899615 Address:North Indurstry Area,Qinhuangdao,Hebei, China Post code: 066000 | |||