- yuanchenwujin@hotmail.com

- +86 335 3899 615

- 中文站

Product Details

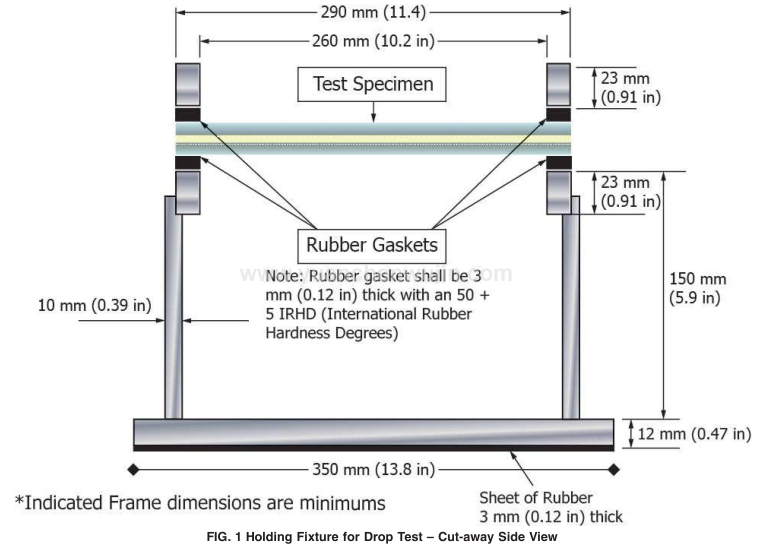

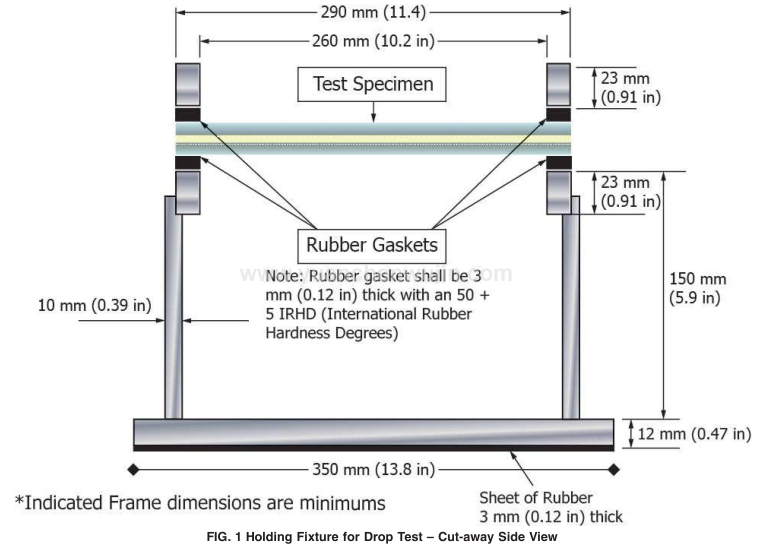

Holding Fixture for Drop Test

ASTM F3007 Standard Test Method for Ball Drop Impact Resistance of Laminated Architectural FlatGlass

Smooth Solid Steel Ball, 2.3 ± 0.1 kg

Support Frame

Test Pieces: 305 ± 10 mm by 305 ± 10 mm

Support Fixture and frame for 227 g ball test and 2260 g ball test of Safety glazing materials. Laminated glass Drop ball impact specimen support.

Various of Ball Drop Test Machine:

Glazing Materials Ball Test Device

Determination of whether the safety glazing material has a certain minimum strength and cohesion under impact from a small hard object

Suitable for impact test of safety glass and tempered glass.

Related Standard:

1). ISO 3537 Road vehicles — Safety glazing materials — Mechanical tests– Clause 6: 227 g ball test, Clause 7: 2260 g ball test

2). GB 15763.3 Safety glazing materials in building Part 3: Laminated glass--Appendix B Drop ball impact specimen support

3) ASTM F3007 Standard Test Method for Ball Drop Impact Resistance of Laminated Architectural Flat Glass

4) EN 356 Glass in building-Security glazing-Testing and classification of resistance against manual attack – Clause 6.1 Hard body drop test

Principle:

Determination of whether the safety glazing material has a certain minimum strength and cohesion under impact from a small hard object

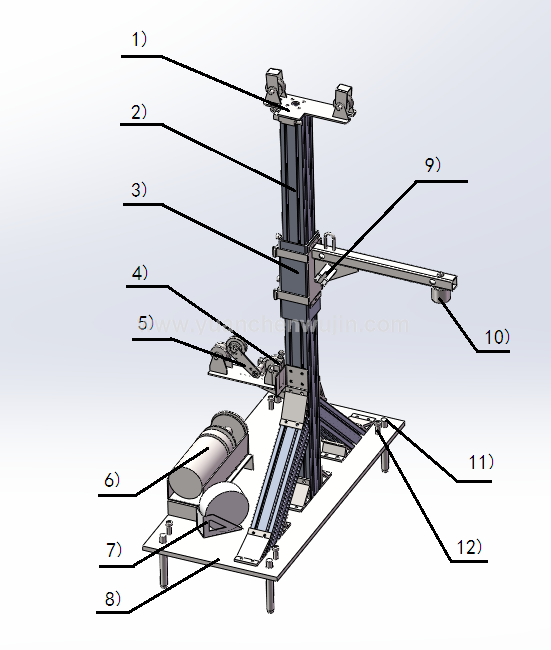

1) Top pulley group 2) Column 3) Square tube 4) Lower limit switch 5) Encoder bracket 6) Motor 7) Wire take-up 8) Base 9) Release device 10) Electromagnet 11) Expansion bolt 12) Leveling screw

Steel Ball: 2260g / 82mm 1040g / 63mm 508g / 50mm 227g / 38mm

Drop Height: 1000mm, 5000mm, 12000mm, Customized

Automatic release and lift. Power: 220V 50Hz 580W

Supporting fixture:

a) Support Size: 350mm*350mm and 660mm*660mm (Customized)

b) Frame width 15mm

c) Steel box height 150mm

d) Rubber Gasket: thickness 3mm, width 15mm, hardness shore A50

e) Interposed sheet of rubber: thickness 3mm, hardness shore A50

Applied Test Pieces Size: 300mm*300mm 610mm* 610mm