- yuanchenwujin@hotmail.com

- +86 335 3899 615

- 中文站

Product Details

Tempered Glass Test Equipment

Safety Glass Quality Testing Equipment

Equipment List:

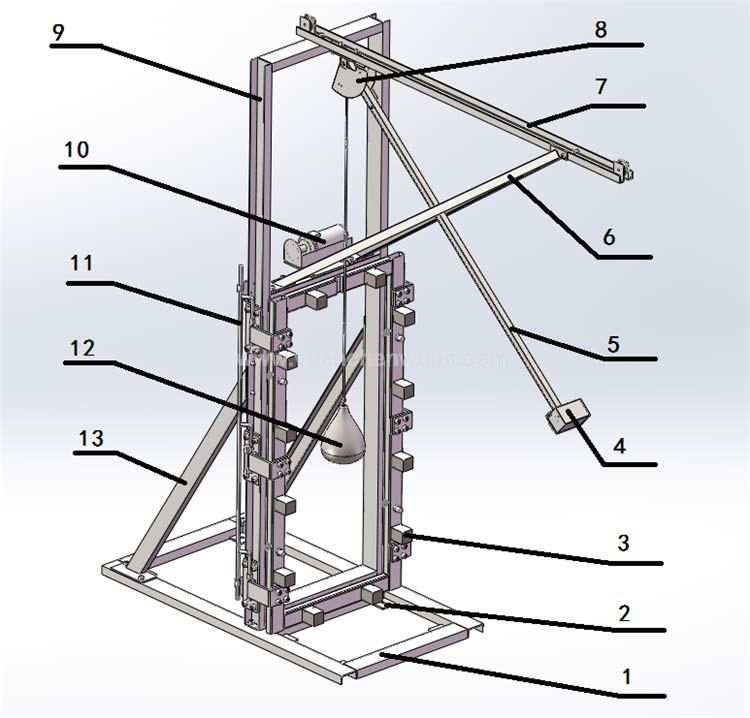

Ball Test Device

Pummel Test Device

Shot Bag 45kg/46kg

Impact Testing Frame

Head Form Test Device

PV Load Test Equipment

Pneumatic Tyres Device

Target Light Source Instrument

Anti Smashing GlassTest Frame

Pneumatic Tyres Impact Device

Insulating Glass Dew Point Meter

Crushing Pen for Tempered Glass

Hard/Soft Pendulum Shock Test for Lifts

Optical Distortion Measuring Instrument

Hardened Steel Ball 2260g/1040g/508g/227g

Laminated Glass High Temperature Test Oven

Mechanical load test equipment for PV Module

Tempered Glass Flatness Measuring Instrument

Impactor for building Glass and Metal Guardrail

Hard and Soft Body Impactors for Opaque Wall Components

Shot bag impact frame

Related Standards:

AS/NZS 2208 Safety glazing materials in buildings – Appendix D: Impact Test

GB 15763.3 Safety glazing materials in building Part 3: Laminated glass – Appendix C: Test device for the impact performance of shot bag

ANSI Z97.1 Safety Glazing Materials Used in Buildings - Safety Performance Specifications and Methods of Test - Clause 5.1: Impact Test

1: Bottom Frame 2: Anchor Bolt 3: Cylinder 4: Electromagnet Release Device

5: Swing Arm 6: Upper Inclined Support 7: Cantilever 8: Scale Dial 9: Main Frame

10: Electric Hoist 11: Control Rod 12: Shot Bag Impactor 13:Lower Inclined Support

Application:

Determining the resistance of glazing materials to impact by the penetration method

Test Frame:

Frame Size: 1900mm*1500mm*3570mm

Samples Size: 1930mm*864mm

Lift: Electric

Release: Auto

Maximum impact height: 1200mm (customized)

Rubber Pad Width: 15mm

Rubber Pad Thickness: 3mm

Rubber Pad Hardness: Shore A50

Impact Shot Bag:

Reinforced leather bag filled with chiller lead shot

Technical Data:

Weight:45kg±0.1kg 46kg±0.1kg

Height: 330mm ± 13mm

Max diameter: 250mm

Leather thickness: 0.15mm

Lead sand size: 2.5mm

Customized: 25kg 48kg

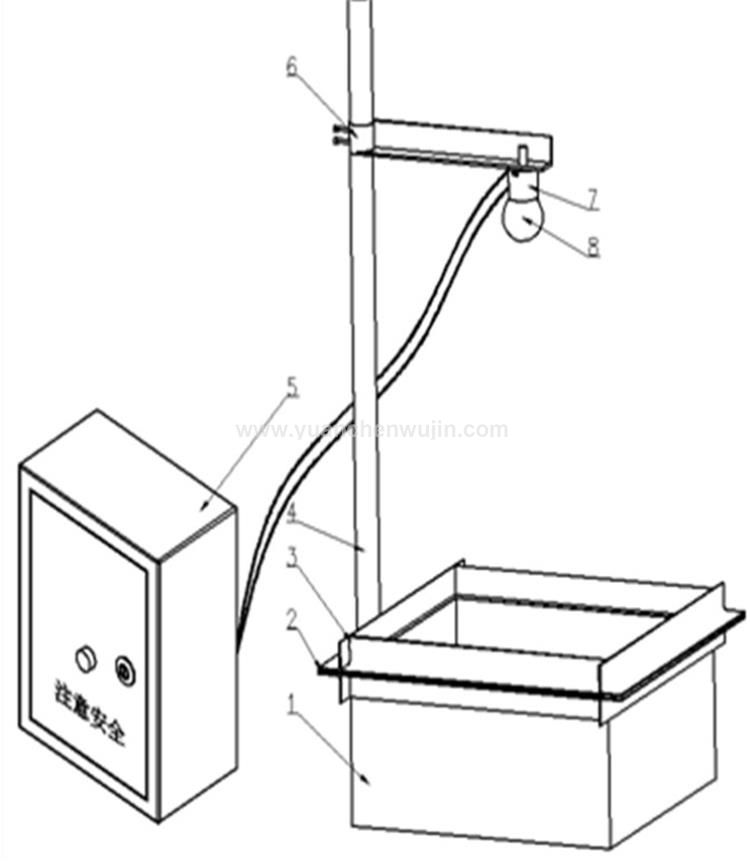

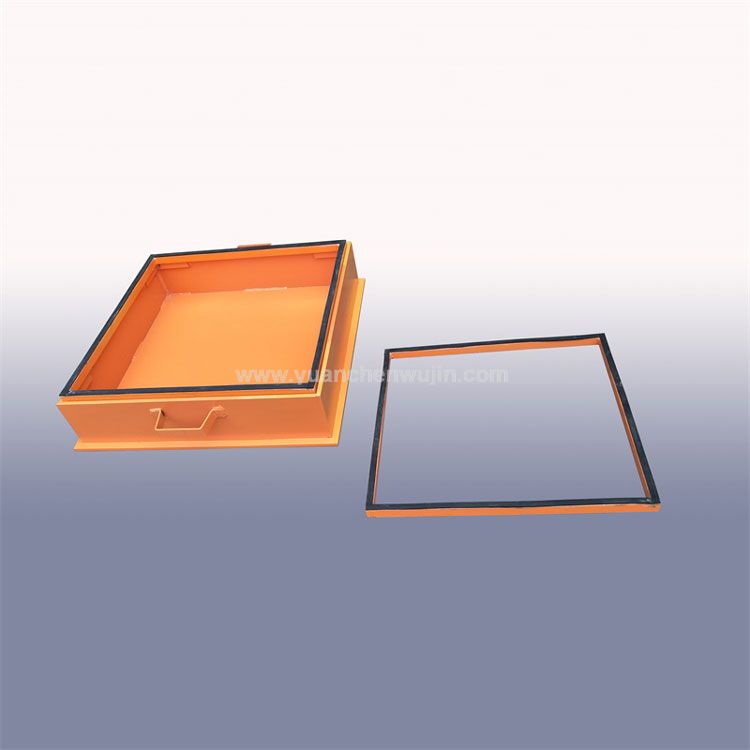

Support and frame for ball tests of Mechanical tests of Safety glazing materials

Related Standard:

ISO 3537 Road vehicles — Safety glazing materials — Mechanical tests – Clause 6: 227 g ball test, Clause 7:2260 g ball test

GB 15763.3 Safety glazing materials in building Part 3:Laminated glass – Appendix B Drop ball impact specimen support

1: support steel box 2: rubber pad 3: steel box pressure frame 4: sample control rod 5: control box 6: sample control rack 7: adsorption device 8: steel ball

Principle:

Determination of whether the safety glazing material has a certain minimum strength and cohesion under impact from a small hard object

Apparatus:Hardness steel ball:

a) 2260g ± 20g, diameter of approximately 82.5mm

b) 227g ± 2g, diameter of approximately 38 mm

c) 1040g ± 10g, diameter of approximately 63.5 mm

d) 508g±3g, diameter of approximately 50 mm

Frame Height: 1000mm, 5000mm, 12000mm, Customized

Automatic release and lift. Power: 220V 50Hz 580W

Supporting fixture:

a) Support Size: 350mm*350mm and 660mm*660mm (Customized)

b) Frame width 15mm

c) Steel box height 150mm

d) Rubber Gasket: thickness 3mm, width 15mm, hardness shore A50

e) Interposed sheet of rubber: thickness 3mm, hardness shore A50

Applied Test Pieces Size: 300mm*300mm 610mm* 610mm

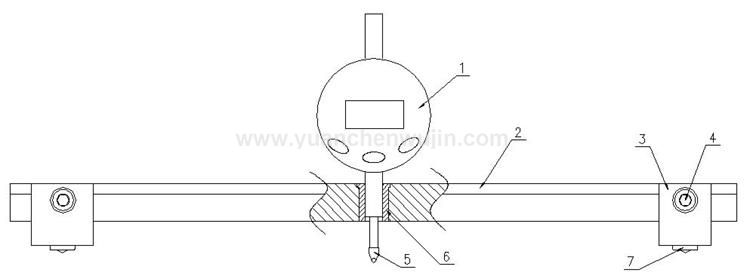

Portable flatness measuring instrument for tempered glass

Related standard:

1) GB 15763.2 Safety glazing materials in building

- Part 2: Tempered glass

Clause 5.4 Camber measuring

2) AS NZS 2208 Safety glazing materials in buildings

Clause 2.5 Flatness requirements

1, Display table 2, Support plate 3, Support block 4, Fixing bolt 5, Measuring head 6, Fixing part 7, Supporting foot

Application:

3) Measurement of arcuate form and wave form of toughened glass

Technical parameters:

4) Resolution: 0.01mm

5) Measuring Span: 300mm-12000 mm ( Customized)

6) Working Temperature: 0~+40℃

7) Working Humidity: ≤80%

Instruction:

8) Adjust the measurement and set up to track the maximum data. Adjust the span of the support block according to request.

9) Adjust the position of measuring head, to ensure that the measuring head is beyond 2mm-3mm of the plane of three support feet.

10) Gently stick the surface of the glass to ensure that three supporting feet are able to touch the glass.

11) Slide the measure location and read the data.

Product features:

12) Continuous measurement and monitoring of the flatness of the glass, data display and recorded.

13) Simple operation, fast measurement, low cost, widely used in the flatness measurement of glass.

14) The specifications of the equipment are various; the measuring span (300mm, 500mm, 800mm, 1000mm, and 1200mm) can be customized according to customers’ requirements.

Impact Steel Ball

Material: Bearing Steel

Hardness: HRC 58-64

Specifications:

Weight: 2260g Diameter: About 82mm

Weight: 1040g Diameter: About 63mm

Weight: 508g Diameter: About 50mm

Weight: 227g Diameter: About 38mm