- yuanchenwujin@hotmail.com

- +86 335 3899 615

- 中文站

In recent years, laser cutting has become an ideal solution for the sheet metal cutting industry due to its high efficiency, high energy density, non-contact processing and flexibility, as well as its advantages in precision, speed and efficiency. The share of laser cutting equipment in metal processing has always taken the lead: whether it is precision cutting of thermoformed sheets, or the creation of shaped parts with complex designs and dimensions such as bodies and tubes. Today, conventional cutting machines are being increasingly replaced by laser cutting equipment with excellent beam quality and high degree of automation.

In addition, thanks to the advancement of domestic fiber lasers, control systems, processing heads and laser cutting machines in the field of technology and cost, these advances have also accelerated the traditional production process, which is mainly based on punching machines and shearing machines, to laser processing. Conversion. Metal cutting is a growth driver for high-power laser processing revenues, especially sheet metal cutting, while high-power and high-brightness direct semiconductor lasers are gaining increasing market share.

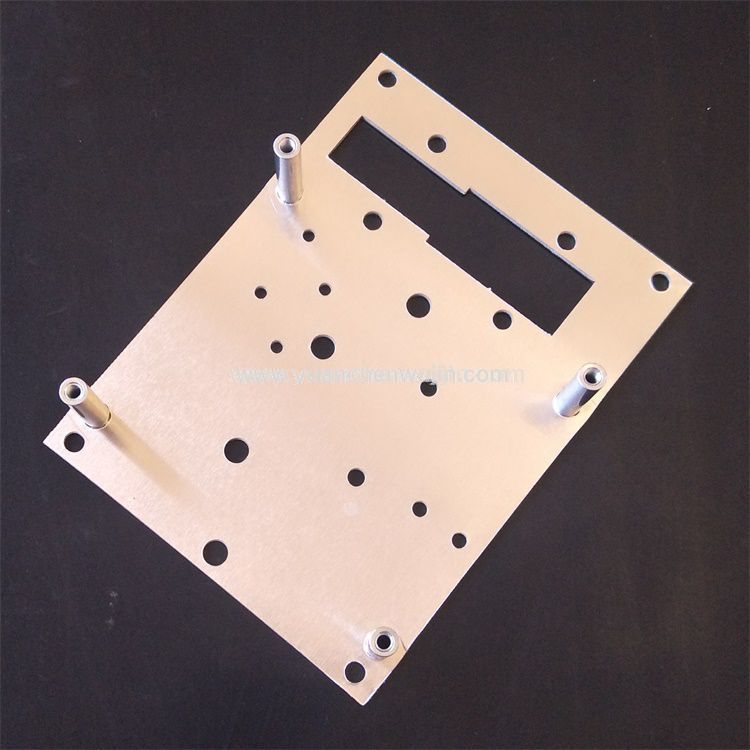

We can supply Sheet Metal Riveting Parts, Metal Hose Sealing Ring, etc. Welcome to contact us.